Our Accreditations

BRC Certified

BRC Certified

ISO Certified

ISO Certified

HACCP Certified

HACCP Certified

Flexweb represents innovation, reliability, and excellence in flexible packaging supply - from roll form to pouch form solutions.

BRC Certified

BRC Certified

ISO Certified

ISO Certified

HACCP Certified

HACCP Certified

With over 40 years of combined experience, we extend beyond being just a supplier to become your trusted partner in flexible packaging solutions.

40+ years of experience in all aspects of flexible packaging supply, from base film production to print, lamination and finishing.

We pledge that our customers will always be heard and communication will always be at the centre of our dealings.

We understand that all needs are different, and flexibility brings competitive advantage to our customers.

Our combination of suppliers, raw materials, equipment and operator skills contribute to industry-leading quality levels.

We are South African and proud of it. Offering Level 4 BBBEE rating and reliable local replacement to imports.

Understanding that our industry and customers are always evolving, and so must we to remain relevant and innovative.

Comprehensive flexible packaging solutions from our state-of-the-art facilities in Germiston and Alrode.

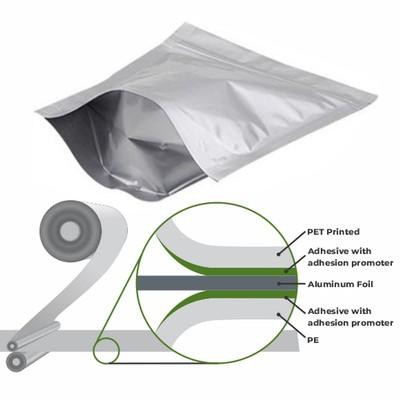

Advanced barrier layer solutions to protect your products and extend shelf life with our specialized material combinations.

Need something specific? Our experienced team will guide you in choosing the ideal solution for your unique requirements.

Get Custom QuoteComplete in-house conversion processes with state-of-the-art equipment and experienced operators.

8 colour flexo up to 650mm wide

9 colour gravure up to 1000mm wide

Ready to discuss your flexible packaging needs? Our experienced team is here to help you find the perfect solution.

Contact us today for a consultation and discover how Flexweb can meet your flexible packaging needs.